Desiccation of medical TPU

Nowadays, TPU is widely used in lots of fields, and even replace PVC to promote performance of many products. It becomes a trend, especially in health-care industry.

In past years, PVC is the main option of the plastic parts for medical equipment, including catheter, infusion bag, infusion tube, etc. However, due to the used medical waste can not be recycled, it has to be incinerated. When PVC medical waste is burned, it will produce toxic gas to make negative influences on environment and human’s health. Thus depending on the more and more mature technology, TPU is replacing PVC in health-care industry gradually. But TPU has to be desiccated before producing because of its feature of moisture absorption.

Here we talk about Pellethane, a kind of medical TPU from Lubrizol. Compared with other kinds of TPU, the medical one has higher standard on its desiccation. For most aromatic TPU, the moisture content should be lower than 0.02%. Otherwise, the moisture will affect the produce process or even the final products. But for medical TPU, the moisture content should be controlled at 0.01% or below. Generally, desiccating TPU for 2-16 hours can reach the moisture content standard.

But the drying time should depends on specific type of TPU. Usually the hardness of TPU, the types of dryers and desiccating temperature will be the factors. For example, if Pellethane TPU was exposed in normal atmosphere, the drying temperature should be at 65-93 ℃ by using hopper dryer.

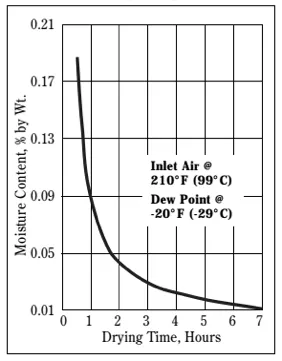

There is the typical drying curve for Pellethane TPU below.

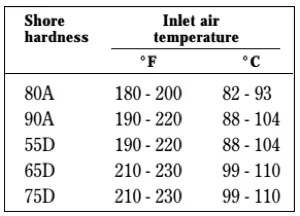

Besides, TPU with different hardness also needs different drying temperature. See the drying temperature of Pellethane TPU with several different hardness in the below table.

The longer drying time and higher drying temperature make TPU has less moisture content. However, the too-long drying time or too-high drying temperature will make us obtain sticky TPU material, which will increase the difficulty during produce process.

Ps. Reference from Wechat Official Account: Lubrizol LifeScience